My Favorites

Share

DETAILS:

| stock number: | 723540 |

| location: | Phoenix, AZ |

| make/model: | Jeep Wrangler TJ - Sahara |

| year: | 1998 |

| condition: | good |

| cylinders: | 6 cylinders |

| drive: | 4wd |

| fuel: | gas |

| odometer: | 71,727 |

| paint color: | white |

| title status: | clean |

| transmission: | automatic |

| type: | SUV |

Request Shipping Quote

Order Inspection

Contact Seller

DESCRIPTION:

Purchased Jeep from dealer in 1999. It had around 21,000 miles when purchased. It has 71,727 miles now. This Jeep was purchased to use specifically on weekends here in Arizona. It was built to be a reliable heavy duty built vehicle to go practically anywhere in the Arizona back country and get my wife and I home safely. It has been garage kept the past 26 years. No kids, pets or smoking.

Jeep came with an OEM hardtop, full hard doors, 4.0L, I6 engine, automatic transmission and air conditioning. All in perfect working condition. NO LEAKS!!!

Upgrades include the following:

INTERIOR:

Basically stock Sahara interior. Very clean, Front seats in perfect condition.

The center dash bezel has been modified. The ash tray was removed and an identical OEM switch bezel was securely fastened in place which gives a factory look and allows for more switches for electrical items, the ARB air lockers and onboard air switches.

A lighted air pressure gauge is installed to keep an eye on the on board air system.

A flush mounted winch cable plug was installed for the winch to give another option on how to control the winch so you do not need to feed the cord from the winch through a window.

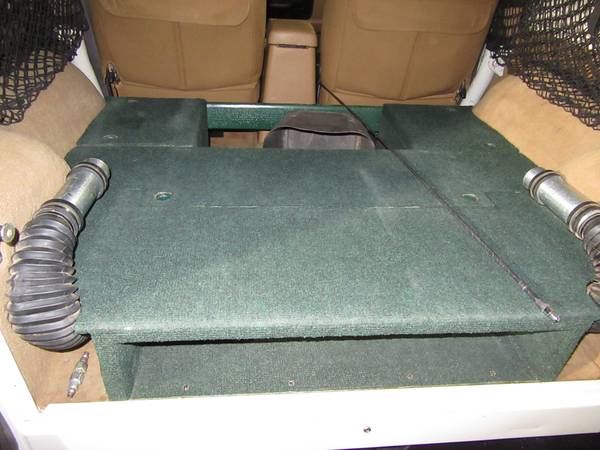

The rear seat has been removed and carefully stored. A custom built, multi compartment unit with lids is installed in back which gives you a flat useable surface to haul all your fun stuff including an area for a cooler. The 6” deep compartments were built to hold and store items like; Tools, spare parts, U-Joints, oil, recovery gear, etc. The compartments have “hinged” lids and were built for safety. “Wing” bolts screw down the lids to keep the compartments closed in case of a roll over or severe off camber situations.

A light weight, easy to remove shelf is installed above the back area for additional storage. The shelf is hinged and the shelf by the back tail gate can be lifted and hooked up for easy access to the lower access area.

Soft sided 40 caliber gun holster installed on driver side of center console.

1 PERSON BED:

I built a quick assemble bed to be able to sleep in the Jeep. By pushing both seats forward, there is enough room for a 5’8” person to sleep inside on a foam and memory foam custom made mattress. The bed was only used once and that was in my garage to see if it worked and it works well. The mattress was well protected with sheets and a sleeping bag was used to sleep in and to protect the mattress. The mattress has been kept inside my home and stored in a nice travel type golf bag – ready to be tossed in the Jeep for overnight stays.

ENGINE:

Inline 6 cylinder engine has been upgraded to be reliable and a stronger engine to deal with the high speed highways and Arizona inclines. I completed engine upgrades for performance only, not because there was an issue with the motor. These upgrades were installed around 51,000 miles. The upgrades are as follows:

Hesco (brand – Hesco.us) - RV camshaft.

Hesco – Double roller timing chain and gear set.

New (at the time) hydraulic lifters and push rods.

Hesco - All aluminum head, milled to 10 to 1 compression

Chrysler Performance – One piece, swirl polished, stainless steel valves, triple ground

Heavy duty valve springs

Harland Sharp - Aluminum fully adjustable roller rockers

Aluminum valve cover

Upgraded intake manifold from the old “Log” style to the newer intake Jeep installed in later TJ models. Much more air flow with the newer style intake.

Larger diameter throttle body, cannot remember the mm size, but is much larger than stock.

Hesco – Throttle body spacer

Chrysler Performance - High flow fuel injectors

High amp alternator, 120 amps, versus the stock 90 amp alternator.

Custom built air cleaner box which utilizes outside air instead of 150+ degree air under hood.

Expensive Uni-Chip computer "brain box" that CAN BE PROGRAMMED!!! This computer goes between the stock box and the electronics for the engine so the motor can be properly tuned with motor modifications. Has a switch so two different programs can be set-up.

NOTE: This is NOT the cheap plug and play garbage.

Pacesetter header with 2 ½” exhaust all the way back to the muffler.

COOLING:

Two row all aluminum radiator

BRX heavy duty silicone radiator hoses

Hesco – High Flow, Performance water pump. The blades in the pump were designed to slice through the coolant versus the stock unit splashing through it. Dyno showed a 6 hp and 2 ft lb, increase.

Jeep uses the stock mechanical cooling fan as well as an electric pusher fan in front of the radiators if needed when crawling along the trails in high heat.

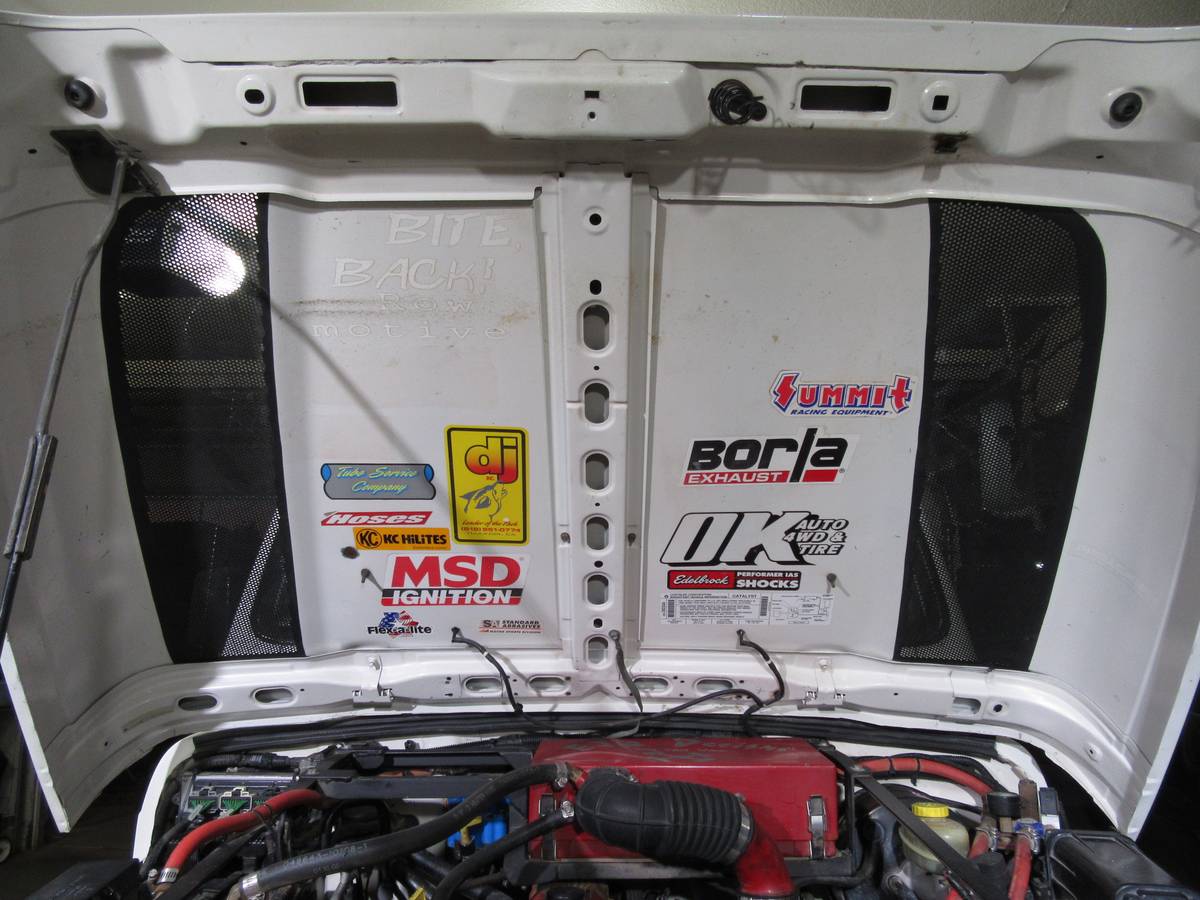

Custom vented hood. I drilled over 10,200 holes in the hood. Did not want to see louvers. The amount of holes drilled is equivalent to a 6”x10” hole on either side of the hood. This helped lower engine and under hood temperatures and keep them stable all the time.

NOTE: The Jeep Never had Overheat Problems. All of this work was for prevention and for safety to make sure (as best as possible) we would not be stranded in the hot desert.

Additional external transmission oil cooler with electric fan.

NOTE: Both electric fans can be switched to turn off manually, turn on manually or switched to turn on at a certain temperature.

DRIVETRAIN:

Transmission

Stock automatic transmission. The upgrades are a heavy duty cast aluminum, deep transmission pan (with cooling fins) and an external oil cooler with electric fan (if needed).

Transfer Case

Upgraded 231 transfer case. Installed Advanced Adaptors short shaft kit. This kit was not a cut down stock shaft but a heavy duty new shaft. The output shaft is much thicker with more splines. Needle bearings used instead of the stock brass bushings.

Driveshaft - Rear

Custom built drive shaft by Tom Wood Driveshafts. The U-Joints were upgraded from 1310 to Spicer 1350. These are much larger and heavy duty for a Jeep.

Driveshaft - Front

Stock front drive shaft that was cut-to-size locally to fit to the new front axle assembly. New Spicer U-Joints installed when re-sized.

Rear Axle

Ford - Nine inch housing

True Hi9 - High pinion center section, 9”gears and heavy duty third member bearing assembly.

456 gears

ARB - Air locker

Braided stainless steel air line for ARB

35 spline axles

Internal (shoe) parking brakes.

Disc main brakes

The wheel bolt pattern has been upgraded from 5 on 4.5” to 5 on 5.5” bolt pattern.

Front Axle

Ford – Nine inch housing

Currie Enterprises - Hi pinion center section – Uses Ford 8.8” gear set.

456 gears

ARB - Air locker

Braided stainless steel air line for ARB

31 spline inner axles

Warn - 30 spline thru hardened outer axles – AND an extra set of outer axles.

Warn – Locking hub kit

Strengthened “C” Knuckles – Plus a spare set of outer knuckles.

Heavy duty CTM U-Joints. These utilize brass bushings instead of needle bearings and are serviceable/repairable/grease able. Reason for brass bushings is, this allows for the journals to be larger making them more heavy duty.

Disc brakes

5 on 5.5” bolt pattern.

SUSPENSION:

The suspension is based on Rubicon Express’s 5.5” long arm lift kit. After installing the kit, trying it out, I realized their kit is junk and needed to be modified to actually work correctly. Below are all the suspension upgrades:

Front Suspension

Three link with track bar front suspension.

5.5” lift coil springs

Upper spring bucket and shock mount were raised 1.5” and re-welded. This allows for 5.5” springs but keeps the center of gravity lower and safer. This lowers the vehicle to feel like a 4” lift but with articulation of a 5.5” lift suspension.

Remote reservoir shocks. They have a ridiculous amount of travel, 14.5” and all of the travel is used. This allows for massive articulation.

Custom built - 2 ¼” x ¼” thick 1060 DOM tubing used for the 3+ foot long lower control arms. The ends are Currie Enterprise’s heavy duty, serviceable, non-rattle Johnny Joints.

Heavy duty upper control arm and track bar installed with Currie’s Johnny Joint ends.

Currie Enterprises – Anti-Rock sway bar system

Custom built – Anti-unload system. TJ’s are notorious for unloading the front springs/front end when going up steep inclines. The system I designed and installed minimizes this as well as helping minimize sway to keep the jeep safer on and off the trail.

Rear Suspension

Triangulated four link which eliminated the need for the pan hard rod/ track bar. This keeps the axle more centered and provides extreme articulation without binding.

Upper and lower spring perches were detached and reset to have the proper angle for a long arm kit. By doing this, this allowed the 5.5” coil springs to be raised up (like the front) 1.25” inches to keep the ride height the same as the front and have a lower center of gravity.

Utilized the Rubicon Express upper and lower chromoly control arms. Front and rear lower control arms are installed to Rubicon Express’s heavy duty cross member.

Remote reservoir shocks with 14.5” travel. Custom built shock mounts made to be able to use all that travel for an incredible amount articulation.

STEERING:

Currie Enterprises – Heavy duty steering linkage.

AGR – Heavy duty Rock Ram hydraulic assist steering system. Kit came with a new heavy duty power steering pump, steering gear box, and a hydraulic rock ram that replaces the stock steering stabilizer damper. The hydraulic hoses that came with it looked cheap and looked like they could fail. I went to a custom hydraulic store in Mesa to have custom high pressure hoses made to make sure this system would not fail. The kit has multiple steering ratios that adjust automatically for low and highway speeds.

NO DEATH WOBBLE or BUMP STEER!

ON-BOARD AIR SYSTEM:

This system is not your typical junk electric air compressors. This Jeep has a fully plumbed air system utilizing a belt driven compressor:

Extreme Outback – Extreme Flow Belt Driven Compressor. This company uses A/C compressors and modifies them to compress air UP TO 150 psi! Simple maintenance. Has 1 zerk fitting that requires high heat grease, like from Red Line, high heat synthetic grease.

The compressor’s air input is attached to the motor’s air cleaner box so the air entering into the compressor is clean, filtered air. The compressed air then passes through another filter prior to entering the ARB solenoids. The air hose then travels to the Bullet Proof (brand) front bumper which is also an air tank. Both front and rear bumpers are air tanks. Each holds about 1.5 to 2 gallons. The front bumper has a ¼” quick disconnect and a ¼ turn ball valve if for some reason you do not want to fill the tanks (bumpers). The air hoses then runs back to the rear bumper (air tank). The rear bumper also has a quick disconnect.

This system fills 35” tires very quickly. You’ll be the envy of your group.

WINCH:

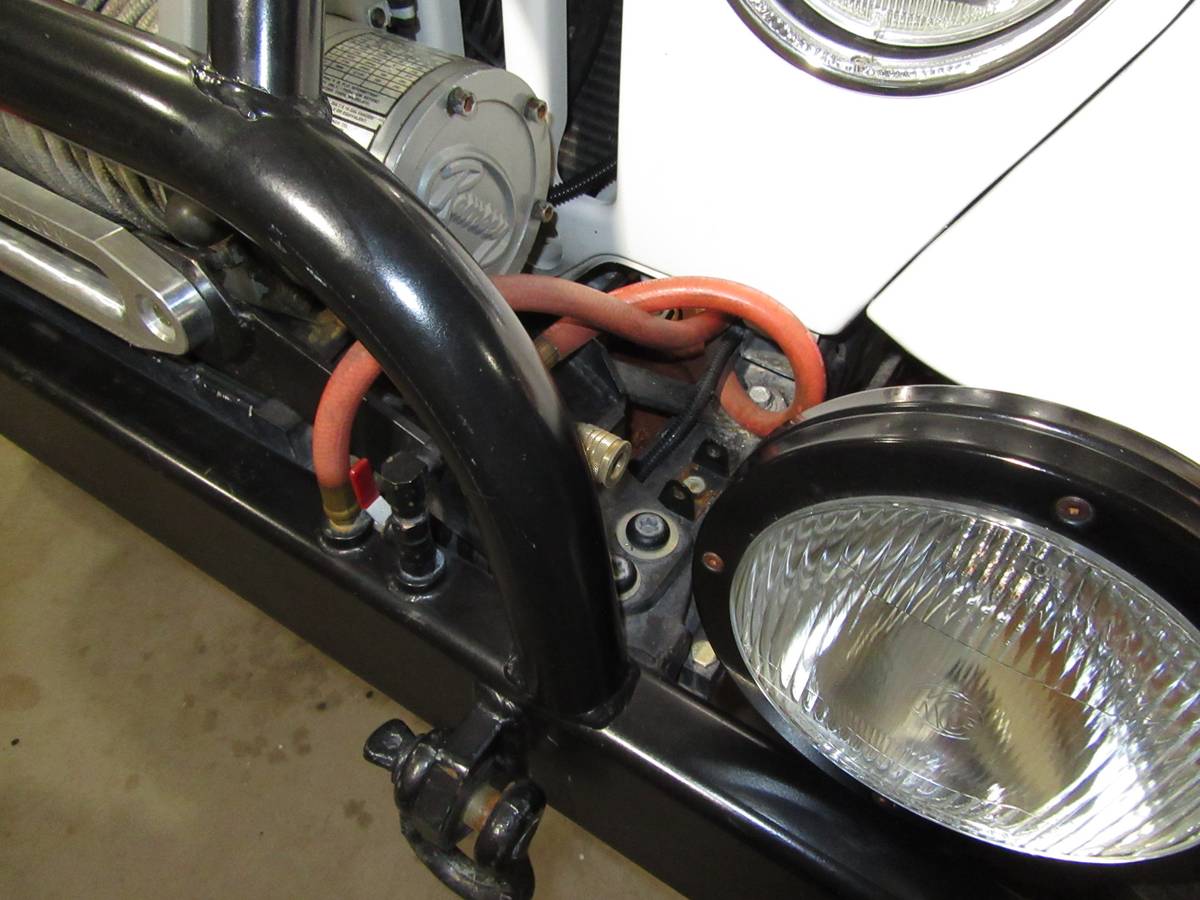

Ramsey Platinum 9500 winch. This winch supports 150 feet of steel cable.

Master Pull synthetic winch line has replaced the steel cable to minimize weight, avoid kinks and eliminate the dangers of a cable under high tension. The winch control cable can be plugged into a plug inside the Jeep as well as out by the winch giving you options.

ACCESSORIES:

Cargo Rack – Custom built, removable rack that mounts to the back swing out tire carrier. NO Rattles! Has tail lights installed in it that plug into the back of the Jeep like a trailer. This should help being pulled over if you have things hanging over the rack and covering the tail lights on the Jeep.

Hard top removal kit to hoist the hard top off and hang it from the garage ceiling.

I have boxes and boxes of extra items. You will need to bring a truck to carry all of the extra stuff including the rear seat.

Jeep came with an OEM hardtop, full hard doors, 4.0L, I6 engine, automatic transmission and air conditioning. All in perfect working condition. NO LEAKS!!!

Upgrades include the following:

INTERIOR:

Basically stock Sahara interior. Very clean, Front seats in perfect condition.

The center dash bezel has been modified. The ash tray was removed and an identical OEM switch bezel was securely fastened in place which gives a factory look and allows for more switches for electrical items, the ARB air lockers and onboard air switches.

A lighted air pressure gauge is installed to keep an eye on the on board air system.

A flush mounted winch cable plug was installed for the winch to give another option on how to control the winch so you do not need to feed the cord from the winch through a window.

The rear seat has been removed and carefully stored. A custom built, multi compartment unit with lids is installed in back which gives you a flat useable surface to haul all your fun stuff including an area for a cooler. The 6” deep compartments were built to hold and store items like; Tools, spare parts, U-Joints, oil, recovery gear, etc. The compartments have “hinged” lids and were built for safety. “Wing” bolts screw down the lids to keep the compartments closed in case of a roll over or severe off camber situations.

A light weight, easy to remove shelf is installed above the back area for additional storage. The shelf is hinged and the shelf by the back tail gate can be lifted and hooked up for easy access to the lower access area.

Soft sided 40 caliber gun holster installed on driver side of center console.

1 PERSON BED:

I built a quick assemble bed to be able to sleep in the Jeep. By pushing both seats forward, there is enough room for a 5’8” person to sleep inside on a foam and memory foam custom made mattress. The bed was only used once and that was in my garage to see if it worked and it works well. The mattress was well protected with sheets and a sleeping bag was used to sleep in and to protect the mattress. The mattress has been kept inside my home and stored in a nice travel type golf bag – ready to be tossed in the Jeep for overnight stays.

ENGINE:

Inline 6 cylinder engine has been upgraded to be reliable and a stronger engine to deal with the high speed highways and Arizona inclines. I completed engine upgrades for performance only, not because there was an issue with the motor. These upgrades were installed around 51,000 miles. The upgrades are as follows:

Hesco (brand – Hesco.us) - RV camshaft.

Hesco – Double roller timing chain and gear set.

New (at the time) hydraulic lifters and push rods.

Hesco - All aluminum head, milled to 10 to 1 compression

Chrysler Performance – One piece, swirl polished, stainless steel valves, triple ground

Heavy duty valve springs

Harland Sharp - Aluminum fully adjustable roller rockers

Aluminum valve cover

Upgraded intake manifold from the old “Log” style to the newer intake Jeep installed in later TJ models. Much more air flow with the newer style intake.

Larger diameter throttle body, cannot remember the mm size, but is much larger than stock.

Hesco – Throttle body spacer

Chrysler Performance - High flow fuel injectors

High amp alternator, 120 amps, versus the stock 90 amp alternator.

Custom built air cleaner box which utilizes outside air instead of 150+ degree air under hood.

Expensive Uni-Chip computer "brain box" that CAN BE PROGRAMMED!!! This computer goes between the stock box and the electronics for the engine so the motor can be properly tuned with motor modifications. Has a switch so two different programs can be set-up.

NOTE: This is NOT the cheap plug and play garbage.

Pacesetter header with 2 ½” exhaust all the way back to the muffler.

COOLING:

Two row all aluminum radiator

BRX heavy duty silicone radiator hoses

Hesco – High Flow, Performance water pump. The blades in the pump were designed to slice through the coolant versus the stock unit splashing through it. Dyno showed a 6 hp and 2 ft lb, increase.

Jeep uses the stock mechanical cooling fan as well as an electric pusher fan in front of the radiators if needed when crawling along the trails in high heat.

Custom vented hood. I drilled over 10,200 holes in the hood. Did not want to see louvers. The amount of holes drilled is equivalent to a 6”x10” hole on either side of the hood. This helped lower engine and under hood temperatures and keep them stable all the time.

NOTE: The Jeep Never had Overheat Problems. All of this work was for prevention and for safety to make sure (as best as possible) we would not be stranded in the hot desert.

Additional external transmission oil cooler with electric fan.

NOTE: Both electric fans can be switched to turn off manually, turn on manually or switched to turn on at a certain temperature.

DRIVETRAIN:

Transmission

Stock automatic transmission. The upgrades are a heavy duty cast aluminum, deep transmission pan (with cooling fins) and an external oil cooler with electric fan (if needed).

Transfer Case

Upgraded 231 transfer case. Installed Advanced Adaptors short shaft kit. This kit was not a cut down stock shaft but a heavy duty new shaft. The output shaft is much thicker with more splines. Needle bearings used instead of the stock brass bushings.

Driveshaft - Rear

Custom built drive shaft by Tom Wood Driveshafts. The U-Joints were upgraded from 1310 to Spicer 1350. These are much larger and heavy duty for a Jeep.

Driveshaft - Front

Stock front drive shaft that was cut-to-size locally to fit to the new front axle assembly. New Spicer U-Joints installed when re-sized.

Rear Axle

Ford - Nine inch housing

True Hi9 - High pinion center section, 9”gears and heavy duty third member bearing assembly.

456 gears

ARB - Air locker

Braided stainless steel air line for ARB

35 spline axles

Internal (shoe) parking brakes.

Disc main brakes

The wheel bolt pattern has been upgraded from 5 on 4.5” to 5 on 5.5” bolt pattern.

Front Axle

Ford – Nine inch housing

Currie Enterprises - Hi pinion center section – Uses Ford 8.8” gear set.

456 gears

ARB - Air locker

Braided stainless steel air line for ARB

31 spline inner axles

Warn - 30 spline thru hardened outer axles – AND an extra set of outer axles.

Warn – Locking hub kit

Strengthened “C” Knuckles – Plus a spare set of outer knuckles.

Heavy duty CTM U-Joints. These utilize brass bushings instead of needle bearings and are serviceable/repairable/grease able. Reason for brass bushings is, this allows for the journals to be larger making them more heavy duty.

Disc brakes

5 on 5.5” bolt pattern.

SUSPENSION:

The suspension is based on Rubicon Express’s 5.5” long arm lift kit. After installing the kit, trying it out, I realized their kit is junk and needed to be modified to actually work correctly. Below are all the suspension upgrades:

Front Suspension

Three link with track bar front suspension.

5.5” lift coil springs

Upper spring bucket and shock mount were raised 1.5” and re-welded. This allows for 5.5” springs but keeps the center of gravity lower and safer. This lowers the vehicle to feel like a 4” lift but with articulation of a 5.5” lift suspension.

Remote reservoir shocks. They have a ridiculous amount of travel, 14.5” and all of the travel is used. This allows for massive articulation.

Custom built - 2 ¼” x ¼” thick 1060 DOM tubing used for the 3+ foot long lower control arms. The ends are Currie Enterprise’s heavy duty, serviceable, non-rattle Johnny Joints.

Heavy duty upper control arm and track bar installed with Currie’s Johnny Joint ends.

Currie Enterprises – Anti-Rock sway bar system

Custom built – Anti-unload system. TJ’s are notorious for unloading the front springs/front end when going up steep inclines. The system I designed and installed minimizes this as well as helping minimize sway to keep the jeep safer on and off the trail.

Rear Suspension

Triangulated four link which eliminated the need for the pan hard rod/ track bar. This keeps the axle more centered and provides extreme articulation without binding.

Upper and lower spring perches were detached and reset to have the proper angle for a long arm kit. By doing this, this allowed the 5.5” coil springs to be raised up (like the front) 1.25” inches to keep the ride height the same as the front and have a lower center of gravity.

Utilized the Rubicon Express upper and lower chromoly control arms. Front and rear lower control arms are installed to Rubicon Express’s heavy duty cross member.

Remote reservoir shocks with 14.5” travel. Custom built shock mounts made to be able to use all that travel for an incredible amount articulation.

STEERING:

Currie Enterprises – Heavy duty steering linkage.

AGR – Heavy duty Rock Ram hydraulic assist steering system. Kit came with a new heavy duty power steering pump, steering gear box, and a hydraulic rock ram that replaces the stock steering stabilizer damper. The hydraulic hoses that came with it looked cheap and looked like they could fail. I went to a custom hydraulic store in Mesa to have custom high pressure hoses made to make sure this system would not fail. The kit has multiple steering ratios that adjust automatically for low and highway speeds.

NO DEATH WOBBLE or BUMP STEER!

ON-BOARD AIR SYSTEM:

This system is not your typical junk electric air compressors. This Jeep has a fully plumbed air system utilizing a belt driven compressor:

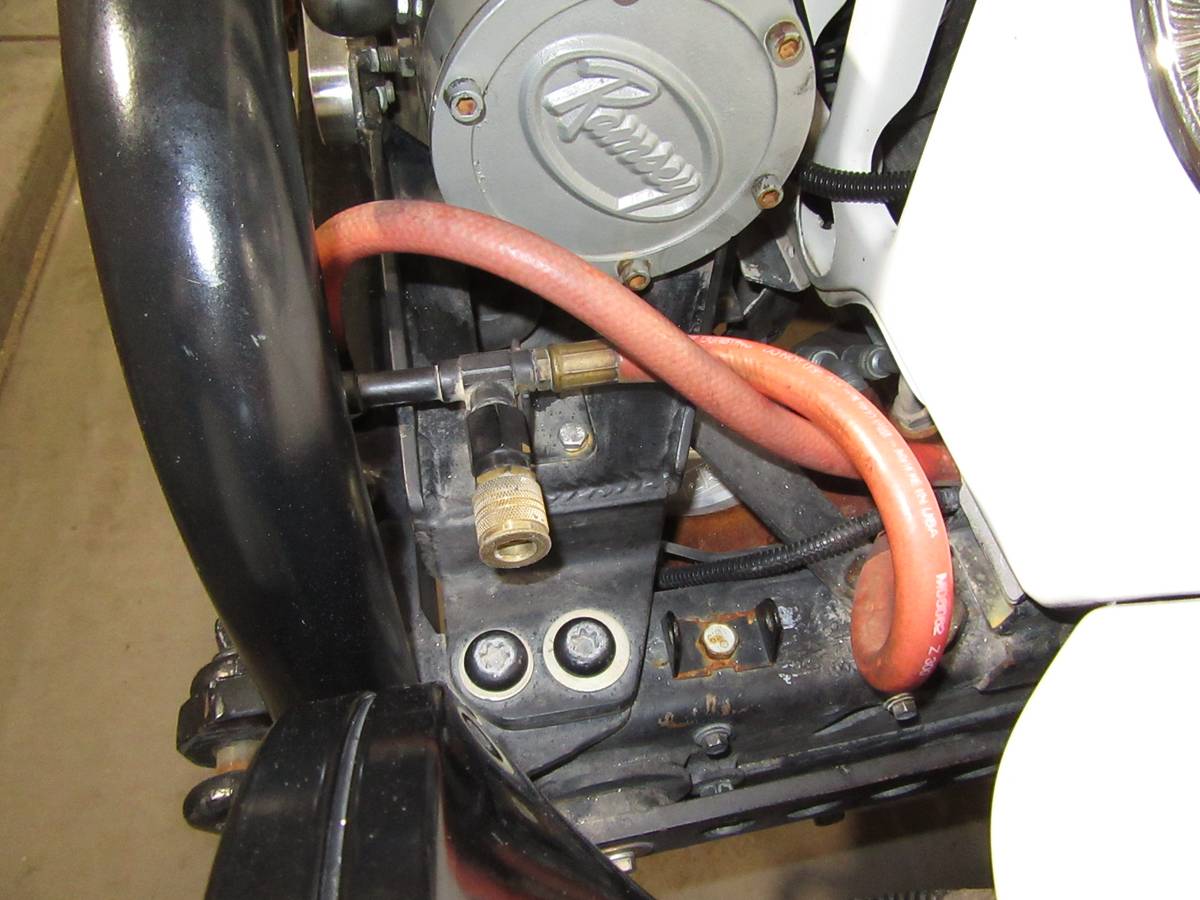

Extreme Outback – Extreme Flow Belt Driven Compressor. This company uses A/C compressors and modifies them to compress air UP TO 150 psi! Simple maintenance. Has 1 zerk fitting that requires high heat grease, like from Red Line, high heat synthetic grease.

The compressor’s air input is attached to the motor’s air cleaner box so the air entering into the compressor is clean, filtered air. The compressed air then passes through another filter prior to entering the ARB solenoids. The air hose then travels to the Bullet Proof (brand) front bumper which is also an air tank. Both front and rear bumpers are air tanks. Each holds about 1.5 to 2 gallons. The front bumper has a ¼” quick disconnect and a ¼ turn ball valve if for some reason you do not want to fill the tanks (bumpers). The air hoses then runs back to the rear bumper (air tank). The rear bumper also has a quick disconnect.

This system fills 35” tires very quickly. You’ll be the envy of your group.

WINCH:

Ramsey Platinum 9500 winch. This winch supports 150 feet of steel cable.

Master Pull synthetic winch line has replaced the steel cable to minimize weight, avoid kinks and eliminate the dangers of a cable under high tension. The winch control cable can be plugged into a plug inside the Jeep as well as out by the winch giving you options.

ACCESSORIES:

Cargo Rack – Custom built, removable rack that mounts to the back swing out tire carrier. NO Rattles! Has tail lights installed in it that plug into the back of the Jeep like a trailer. This should help being pulled over if you have things hanging over the rack and covering the tail lights on the Jeep.

Hard top removal kit to hoist the hard top off and hang it from the garage ceiling.

I have boxes and boxes of extra items. You will need to bring a truck to carry all of the extra stuff including the rear seat.

Posted: Jul 18, 2025